We calibrate a weighing device to understand how it behaves but we adjust the device to change its behavior. So to change the behavior of something firstly, we need to find how it is behaving by calibration and then we can adjust the same. It is important to find the device’s behavior before making any changes to its behavior. Therefore, it is reasonable and common to calibrate a weighing device without adjusting it.

A relationship is developed between a known value (standard) and a measured value by the help of calibration.

Adjusting a balance means that you are intervening in the weighing system, to make sure that the display is set to show the correct nominal value. And Calibration, on the other hand you are testing whether the display is correct and documenting any deviation.

For all units of measurement, there are some standards established as the basis for a particular unit. In the context of weighing devices, standard come in the form of Test Weights. The Test Weight is only classified as checking equipment if it has relevant proof of accuracy. The Test Weight has a certified value and the weighing device is supposed to indicate a value of Test Weight once it is placed upon the weighing device’s receptor. This is how we understand the behavior of the weighing device by calibration using Test Weight of certified value.

We find a relationship between the certified value of Test Weight and the value indicated by the weighing device and finally we can also make analysis on the behavioral aspects of the weighing device.

Selection of appropriate Test Weight is very necessary for your balance. A balance can never be more accurate than the Test Weight used to adjust it, it depends on its tolerance. Accuracy of the Test Weight should correspond to the readout of the balance, rather than something better. SWPI’s Cast Iron Test Weights are intended for use in the Verification or Calibration of Weights and for use with weighing instruments of medium accuracy class or ordinary class. They are manufactured from high quality cast iron and are free of cracks and pit.

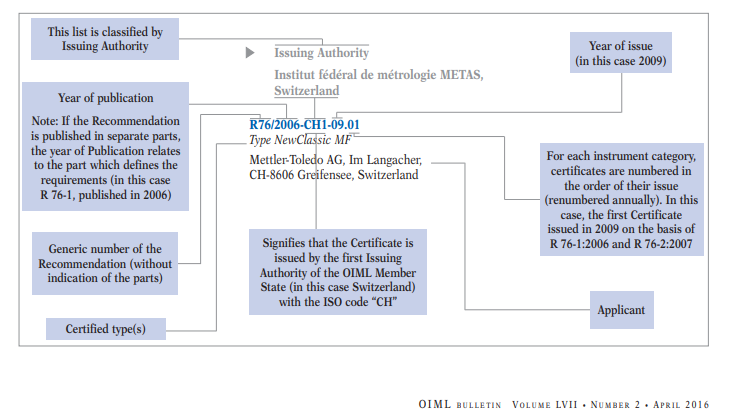

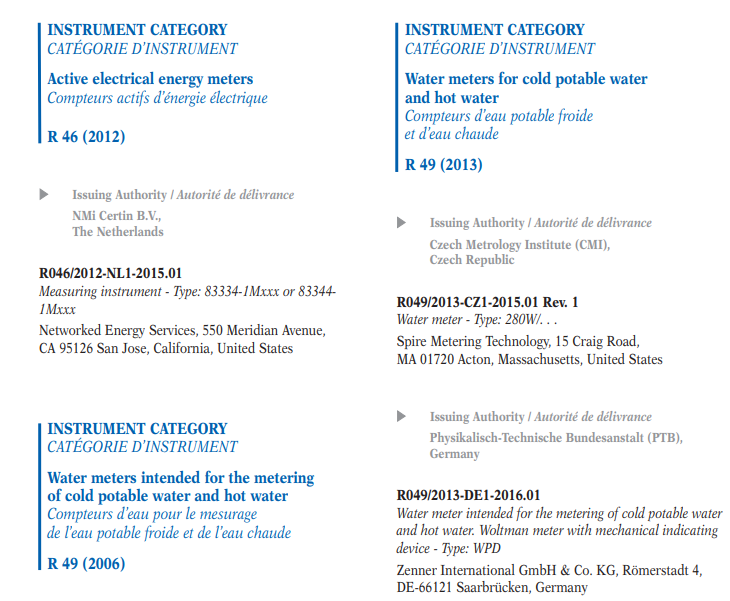

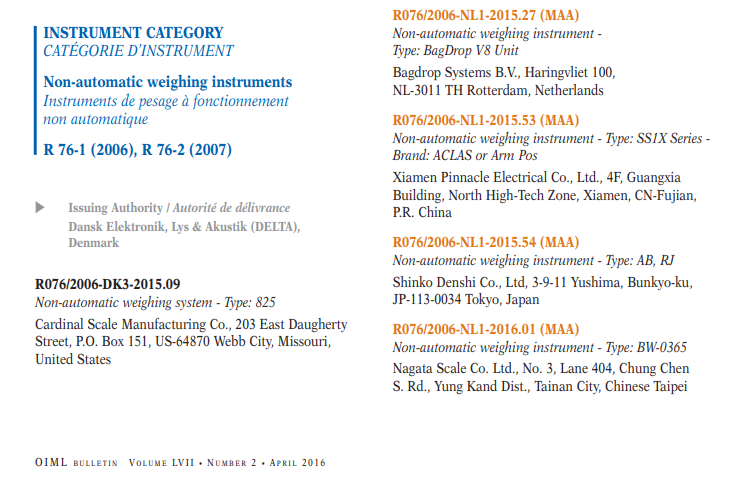

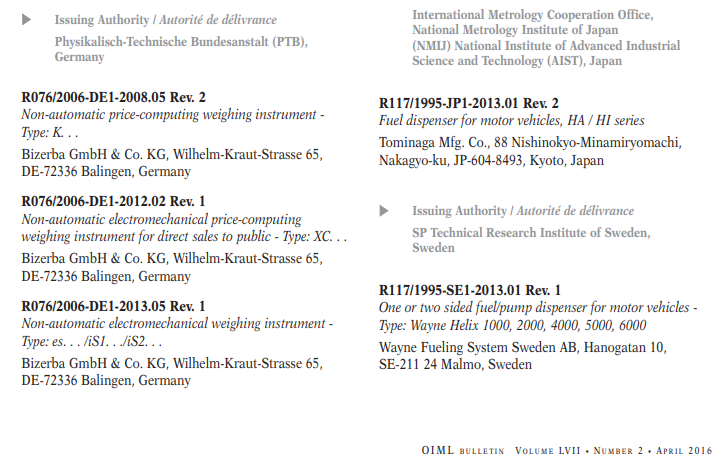

The proper selection of an appropriate Test Weights involve knowing their proper permissible error limit, which are already set according to the OIML standards according to their class. Test Weights manufacturing as per OIML Recommendation R-111 is our specialty. Shanker Wire Products Industries (SWPI) manufactures exclusively Test Weights since 1961.

The surface quality of the Test Weights also plays an important role in the calibration of the balance. The bottom surface of Test Weight should be perfectly levelled so that it touches the receptor in its totality. SWPI’s Test Weight are well known for its Test Weight with satisfactory surface quality which ensures the accurate calibration of the weighing device.

Adjustment is not calibration. You can calibrate a measurement device without adjusting it. Calibration is developing an understanding of a measurement device. Calibration should include the determination of the measurement uncertainty to enhance the understanding of the measuring device.

To enquire about Calibration Test Weights follow the link: